Excellence in Custom Injection Molding

Our Mission

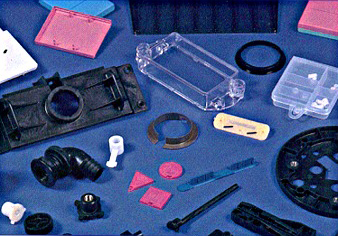

As a custom injection molder, it is the mission of ITP to provide customers with high quality products and outstanding customer service at a fair price. ITP manufactures a diverse set of products for a wide range of industries including the manufacture of medical hardware, computer tape cartridges, mechanical or electrical components, household items, security products, and many other items. Rigorous quality control standards, careful workmanship, and in-process quality inspections ensure a precise fit down to one ten-thousandth of an inch for optimal functionality.

The insert-molding, gear molding, and design capabilities of ITP are unsurpassed, with extensive experience utilizing nearly every type of resin. ITP customers enjoy prompt personal service delivered by knowledgeable professionals. Up-to-the-minute job status reports are available during production. Whatever the application, put our technical expertise and experience to work for you!

Why choose us?

OUR PRODUCTS

ITP manufactures quality products for every industry and for a wide range of applications. Diversity has been our key to success. Whether it be medical, hardware, computer tape cartridges, mechanical or electrical components, household or security items, ITP’s precise workmanship and in-process quality inspections ensure the product’s fit and function. Our insert-molding, gear molding and design capabilities are second to none.

FACILITIES

ITP’s offices, engineering, and production are housed in three state of the art fireproof facilities totaling over 36,000 sq. ft. Our location along the scenic St. Croix Rivaer provides ITP employees with vast recreational opportunities every season of the year. The quality of life that thrives in this beautiful area of the country fosters a positive spirit toward our work, a spirit which is reflected in our commitment to our customers.

Productivity is optimized in an environment arranged for efficient workflow and a rigorous quality control program of monitoring both in-process and final production. All products are carefully approved prior to shipment. Back-up equipment assures continued production during periods of regular machine service and maintenance.