Quality Control

Because our business is the production of precision parts, ITP has a quality-trained staff totally committed to statistical process control (SPC) and continuous improvement in product quality, detail, and uniformity.

Our comprehensive quality efforts involve every employee in every department. Our work with the ISO 9000 and Sigma quality programs has provided the statistical tools and processes by which we perform our jobs and evaluate our products. Quality teams in all departments regularly discuss ways in which we can improve our production processes to better meet specific customer requirements.

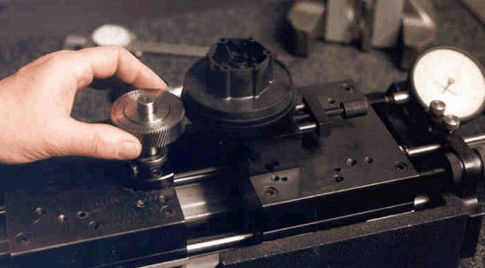

ITP Quality Control combines sophisticated measurement equipment with the interfacing of your CAD data to create unparalleled process control. Up-front and around-the-clock prevention techniques insure the maintenance of the highest standards of workmanship. We maintain a set of master gage blocks, traceable to the United States Bureau of Standards, and file documentation of certification for al measuring and testing equipment.

Innovation, consistent results, and dedication to quality have enabled us to keep pace with the changing technological demands of the industry and the specific needs of our customers.

Our goal is to provide an acceptable product 100% of the time. Our success is measured by your statifaction!